Post by barleybeard on Feb 12, 2017 17:09:37 GMT -7

Howdy. This thread will attempt to document the successes and failures of my first experimental build -- based off of a PipeSmith Legend bowl and shank. Any and all questions and comments welcome!

Update 1 - 1/16/17

After chatting with the PipeSmith over email and coming to terms with the fact that all the beautiful Limited Series pipes are spoken for, I place an order for

The rest of that week was more or less wasted staring at shapes and styles of pipes that struck my fancy. In the end, I decided to shoot for something with strong angles, high contrast colors, and an atomizer cover. I want this thing to make a statement, a coffee table conversation starter! With the overall style decided, I dug into atomizer research. The world of rebuildables had a bit of a learning curve, so I also looked at cheaper off-the-shelf options for the best mouth to lung experience. I ended up ordering two 22mm diameter atomizers:

Update 2 - 1/20/17

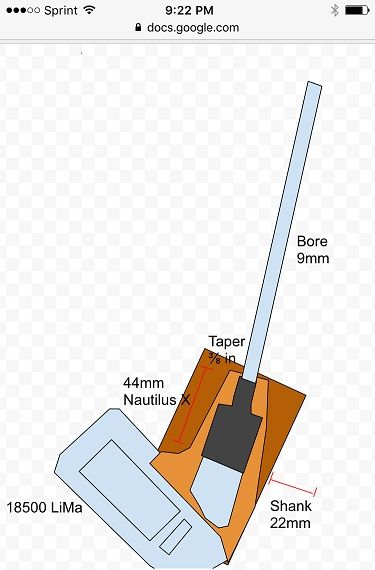

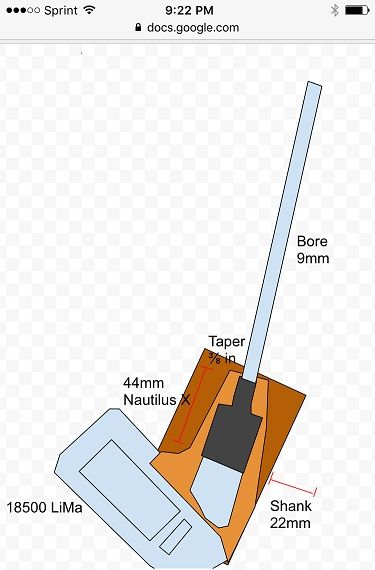

I've been stewing on how to accomplish a slip cover or something similar with limited tools and think I have a loose idea of boring a 7/8" hole through the center of a turning blank, and meeting that hole with a 3/8" drill through the other side. I put together a really rough sketch just to make sure this conceptually made sense. The only issue would be working blind to the angle of the shank from the bowl, but with enough extra material I should be able to accommodate any angle.

Update 3 - 1/21/17

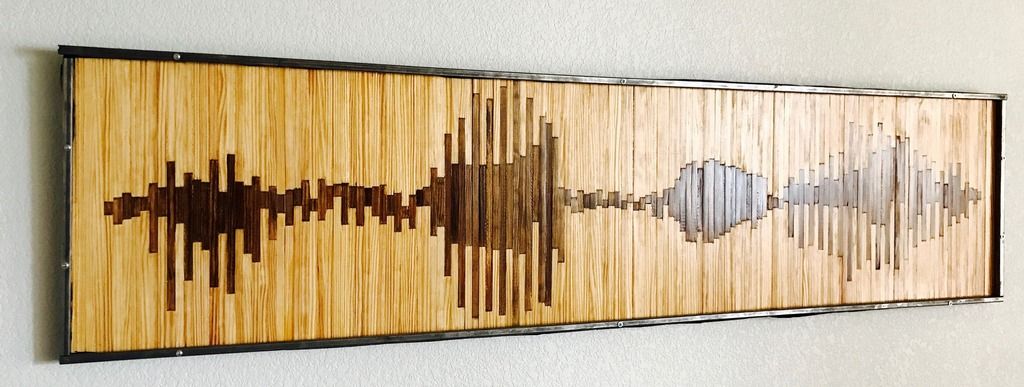

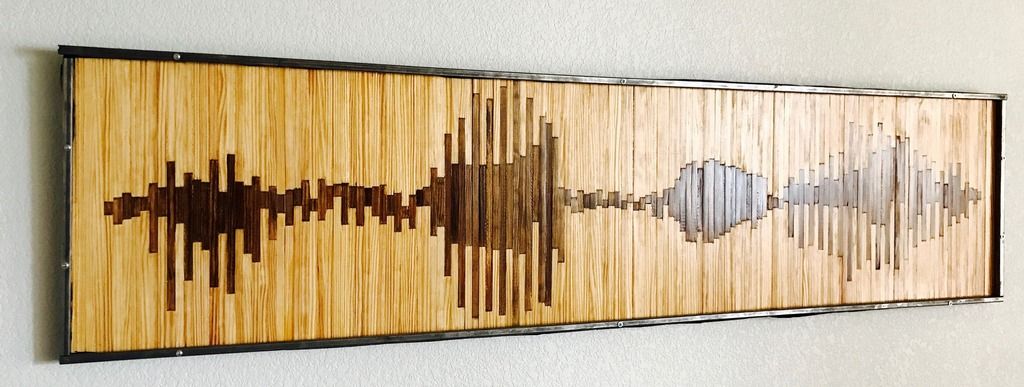

Time to actually do something. I dug around the garage and found about ten feet of 1"x2" black walnut left over from a wall piece I made for my wife last year. I tried to do some grain matching and marked off pieces that I think would work well with the angle of the "elbow" that I want coming from the shank. I cut four sections, I've learned that I always mess up so the age old "measure twice" wisdom for me means I should always have a backup. Slapped on some wood glue, and clamped for the night. I'm slightly concerned about the glue's performance when the coils heat up, but time will tell.

For any interested, forementioned leftover walnut/pine project:

Update 4 - 1/29/17

Nautilus came in!

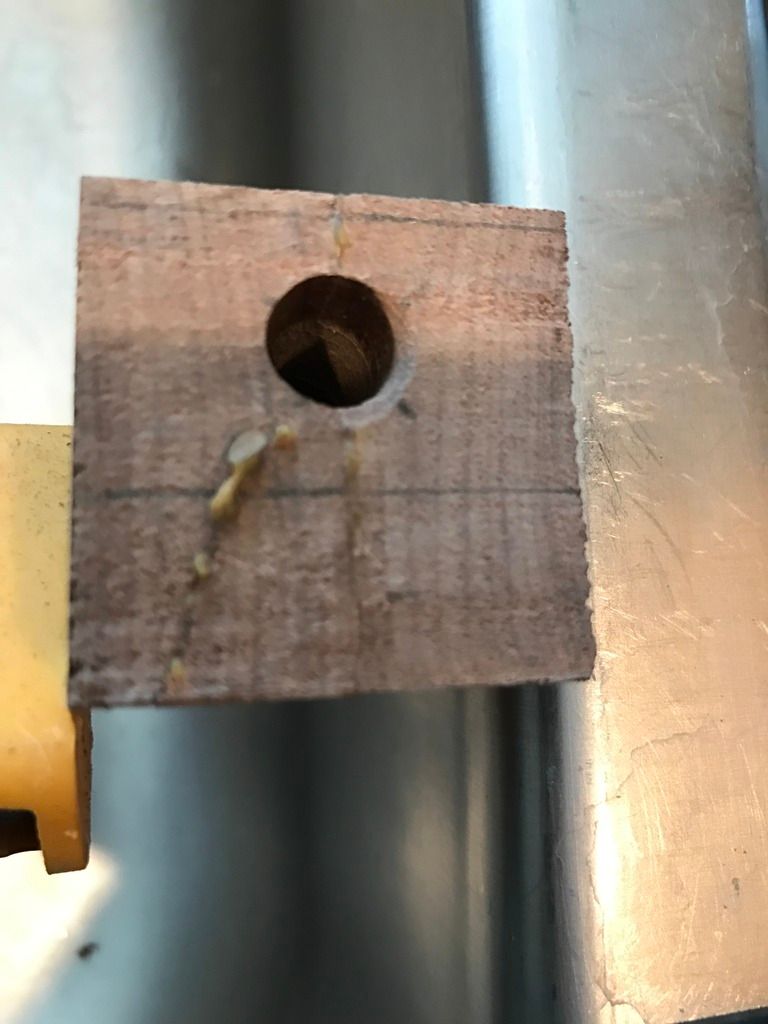

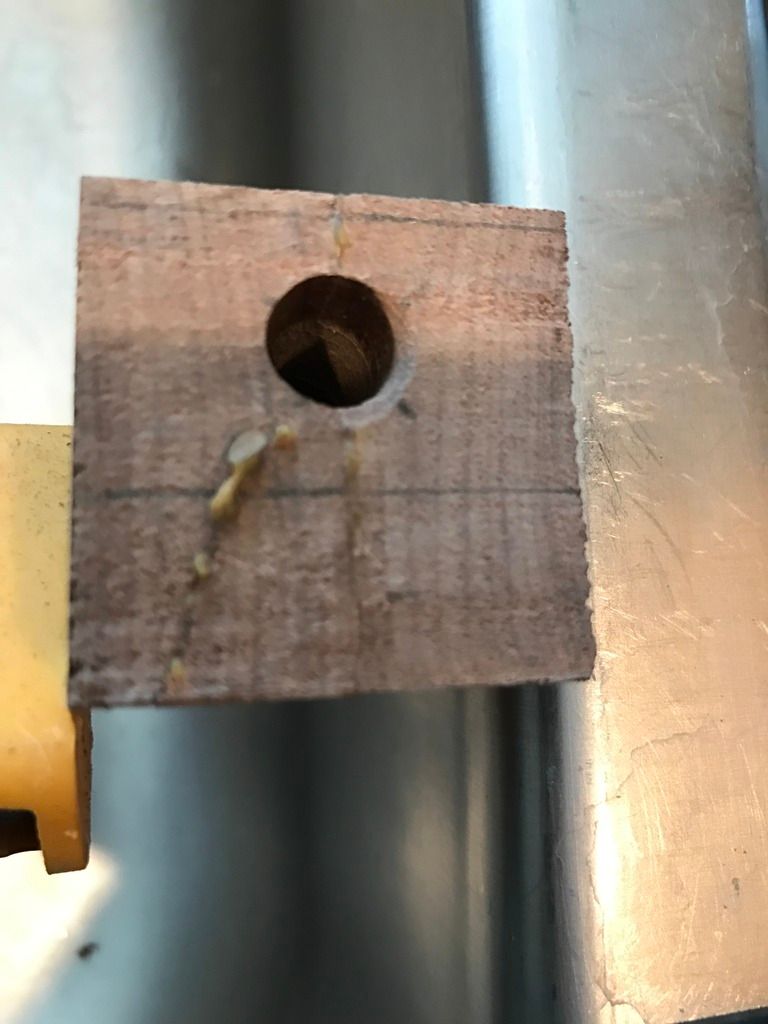

Now I can double check my measurements and start boring my 7/8" hole. Looks like everything will check out. One of the walnut blanks cracked in the top right corner from the altitude change, so I glued it back together. Hoping the fissure gives it some extra character? Here is how I marked up the blanks and started the drilling process.

The 22mm atomizer fits like a glove in the 7/8" channel, and with a little coaxing the shoulder seats up into the smaller 3/8" drilled hole.

Update 5 - 2/5/17

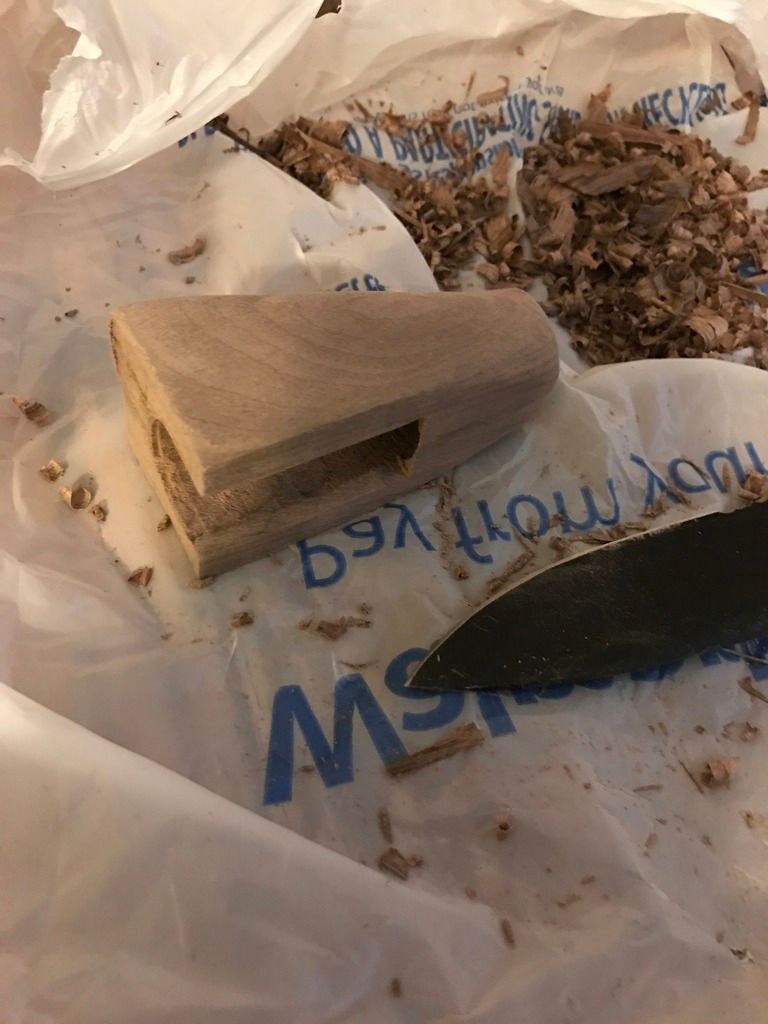

Had to go pick up a tiny hack saw to do some of the detail work, I'm afraid with how thin some of the side walls are, the bandsaw is one jump away from shredding this thing. I trimmed out a channel on the underside so that the heat sync can still have some amount of air to exchange energy with, and so I can see how much juice is left without taking the cover off. The channel looks a bit long and a bit rough, mostly because I suck at hand-boring, but secondly because I still don't know the length and angle of the shank. Presumably a good chunk of the end of this will be cut off at an angle for the finished product.

Pretty satisfied with the internals, I did some rough shaping with the hack saw based on my original lines

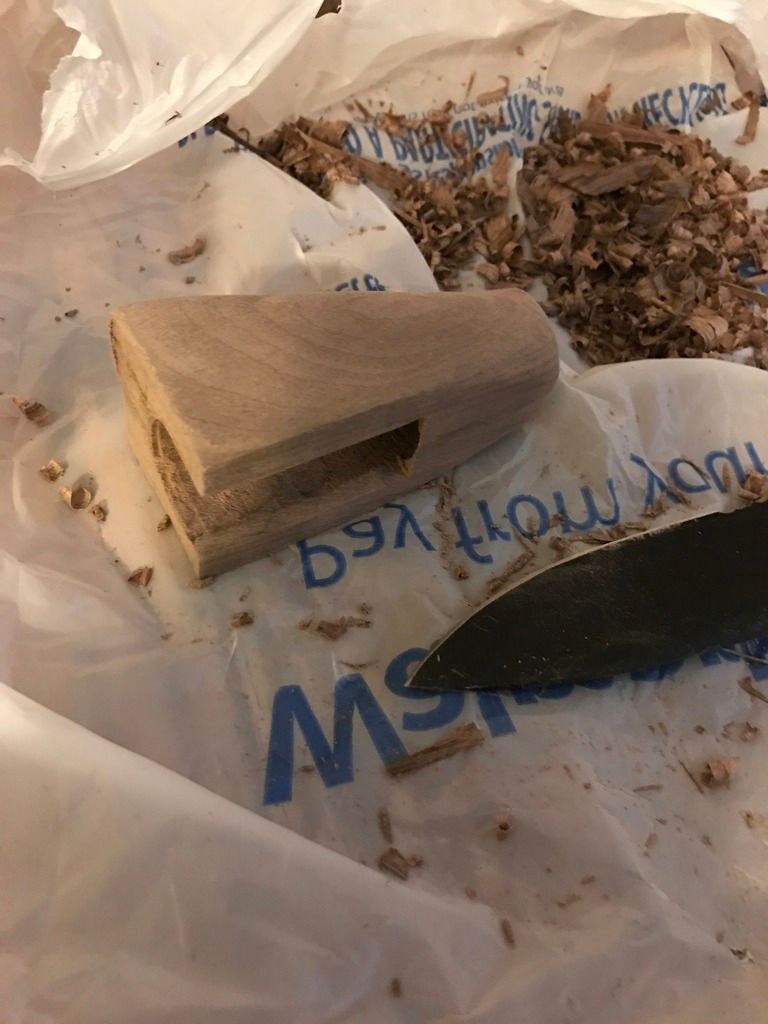

After shaping, time to settle in for some good old fashioned Netflix n' Whittle with a Benchmade Nimravus

Update 6 - 2/12/17

Can't wait to actually get the pipe body! Finished up shaping the elbow/cover.

Then hit it with some 100 grit sandpaper, then 280. I'm sure I'll do more shaping once I see how it will look mated to the shank. I'm thinking I may do some joinery techniques for a bit of a friction set, instead of just relying on the mouthpiece to keep the slip cover snug against the bowl. Here's how it looks sanded. It is taking a lot of energy not to prematurely throw some linseed oil on it

Update 1 - 1/16/17

After chatting with the PipeSmith over email and coming to terms with the fact that all the beautiful Limited Series pipes are spoken for, I place an order for

- PipeSmith Legend Series Trapper Body

- PipeSmith 5" Churchwarden Taper Bore Stem Kit

The rest of that week was more or less wasted staring at shapes and styles of pipes that struck my fancy. In the end, I decided to shoot for something with strong angles, high contrast colors, and an atomizer cover. I want this thing to make a statement, a coffee table conversation starter! With the overall style decided, I dug into atomizer research. The world of rebuildables had a bit of a learning curve, so I also looked at cheaper off-the-shelf options for the best mouth to lung experience. I ended up ordering two 22mm diameter atomizers:

- Kayfun V3 Mini (on backorder)

- Aspire Nautilus X in Copper

Update 2 - 1/20/17

I've been stewing on how to accomplish a slip cover or something similar with limited tools and think I have a loose idea of boring a 7/8" hole through the center of a turning blank, and meeting that hole with a 3/8" drill through the other side. I put together a really rough sketch just to make sure this conceptually made sense. The only issue would be working blind to the angle of the shank from the bowl, but with enough extra material I should be able to accommodate any angle.

Update 3 - 1/21/17

Time to actually do something. I dug around the garage and found about ten feet of 1"x2" black walnut left over from a wall piece I made for my wife last year. I tried to do some grain matching and marked off pieces that I think would work well with the angle of the "elbow" that I want coming from the shank. I cut four sections, I've learned that I always mess up so the age old "measure twice" wisdom for me means I should always have a backup. Slapped on some wood glue, and clamped for the night. I'm slightly concerned about the glue's performance when the coils heat up, but time will tell.

For any interested, forementioned leftover walnut/pine project:

Update 4 - 1/29/17

Nautilus came in!

Now I can double check my measurements and start boring my 7/8" hole. Looks like everything will check out. One of the walnut blanks cracked in the top right corner from the altitude change, so I glued it back together. Hoping the fissure gives it some extra character? Here is how I marked up the blanks and started the drilling process.

The 22mm atomizer fits like a glove in the 7/8" channel, and with a little coaxing the shoulder seats up into the smaller 3/8" drilled hole.

Update 5 - 2/5/17

Had to go pick up a tiny hack saw to do some of the detail work, I'm afraid with how thin some of the side walls are, the bandsaw is one jump away from shredding this thing. I trimmed out a channel on the underside so that the heat sync can still have some amount of air to exchange energy with, and so I can see how much juice is left without taking the cover off. The channel looks a bit long and a bit rough, mostly because I suck at hand-boring, but secondly because I still don't know the length and angle of the shank. Presumably a good chunk of the end of this will be cut off at an angle for the finished product.

Pretty satisfied with the internals, I did some rough shaping with the hack saw based on my original lines

After shaping, time to settle in for some good old fashioned Netflix n' Whittle with a Benchmade Nimravus

Update 6 - 2/12/17

Can't wait to actually get the pipe body! Finished up shaping the elbow/cover.

Then hit it with some 100 grit sandpaper, then 280. I'm sure I'll do more shaping once I see how it will look mated to the shank. I'm thinking I may do some joinery techniques for a bit of a friction set, instead of just relying on the mouthpiece to keep the slip cover snug against the bowl. Here's how it looks sanded. It is taking a lot of energy not to prematurely throw some linseed oil on it